Specialty

ECL

The Challenge Printing Company proprietary PatientDirect® ECL design provides the optimal solution for labeling with multi-language applications and extensive regulatory guidelines.

By utilizing a customizable combination of inks, varnishes and overlaminates, we enable pharmaceutical manufacturers to achieve a better quality ECL for their products. This process allows for high quality imaging of human readable information, excellent scanability of 2D codes, and increased packaging line/laser marking speeds.

Our PatientDirect® ECL design, ensures both a higher number of labels per roll and absolute consistency between the graphics of the base label and the extended content booklet. This design is the solution needed to optimize packaging lines and create a more streamlined process. Our PatientDirect® ECL solution is yet another illustration of our commitment to bring Best Total Value to pharmaceutical manufacturers around the world.

LA - Label Assemblies

The Challenge Printing Company line of specialty components includes Label Assemblies. The construction of a Label Assembly consists of a folded leaflet with a label adhered to it. The Challenge Labels Assemblies are the perfect solution for applications that require dynamic components with removable parts for use by the pharmacist or end user. Label assemblies are an effective and convenient solution for the application of 2D barcodes, directions for use stickers, and dosage reminder stickers. Users can simply peel off the sticker and use as indicated.

MPL - Multiply Label

The Challenge Printing Company proprietary MultiPly® label is a two-layer label that offers more label “real estate” and can be used to include Drug Facts, important product information and patient instructions.

The creation of our MultiPly® label was born after interviewing several pharmaceutical package engineers and discovering that there was a need for a solution that addressed the requirement for additional real-estate while maintaining efficiency on production lines.

The Challenge MultiPly® label is a prime example of Challenge 360 at work. Challenge 360 encompasses all aspects needed for planning and production. We offer our customers technical development assistance, brand consistency among entire portfolio; brand protection solutions; rigorous quality control; and state-of-the-art printing capabilities.

PBL - Peel Back Label

The Challenge Printing Company Peel Back Label offers our customers an option for additional “real estate” on the label. Our peel back solution allows end users to lift a corner of the label and reveal additional product information, such as drug facts or patient instructions.

The construction of the Peel Back labels offer a face label, typically containing pertinent drug information, and a backside that can be imprinted with any additional information required.

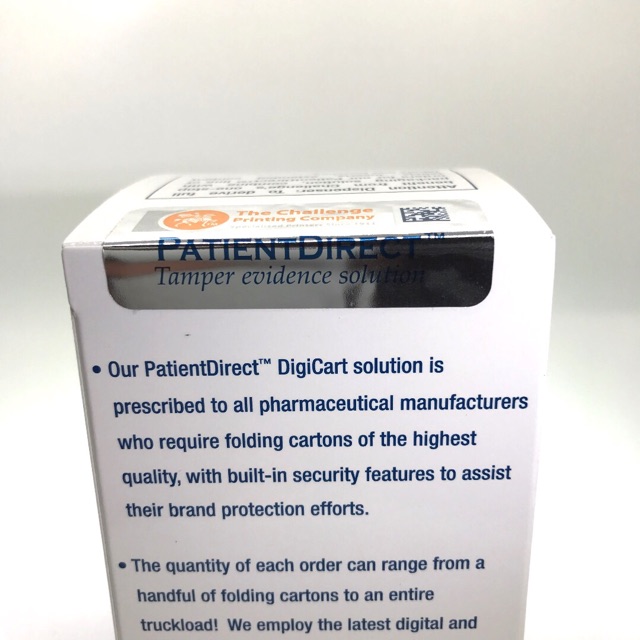

TES1 - Tamper-Evident Seal 1

At The Challenge Printing Company, our exclusive designs and production of security components are a top priority.

Tamper Evident Seals form part of our extensive portfolio of security device offerings. Tamper Evident Seals help our customers ensure the end product’s integrity and/or authenticity. Additionally, the Tamper Evident Seal provides security to indicate the product has not been tampered with.

The Challenge Printing Company is a charter member of the North American Security Products Organization (NASPO). As such, we are charged with the responsibility of creating widely accepted security standards for our industry.

TES2 - Tamper-Evident Seal 2

An alternative type of Tamper Evident Seals offered by The Challenge Printing Company are Tamper Evidence “VOIDs”. This class of Tamper Evident Seal also falls under our extensive line of security device offerings.

Tamper Evident “VOIDs” are devices (labels/seals) that leave a permanent message (often “VOID” or “OPENED”) on the product, immediately upon removal of the device. The residue message can be customized to meet brand owner needs. This type of Tamper Evident Seal helps ensure the product’s integrity and/or authenticity to indicate the product has not been tampered with. A common application of Tamper Evident “VOIDS” include closures for pharmaceutical cartons.

The Challenge Printing Company is a charter member of the North American Security Products Organization (NASPO). As such, we are charged with the responsibility of creating widely accepted security standards for our industry.